Treatment | Pumping | Desalination

A large part of our activity is focused on the environmental sector and water treatment.

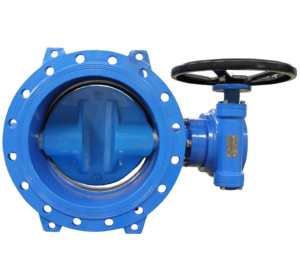

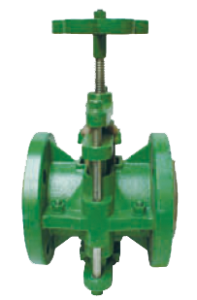

Our products are adapted to meet the needs of drinking water treatment plants (ACS and WRAS certificates) and wastewater treatment plants thanks to our complete ranges of butterfly valves, knife gate valves, check valves, resilient seat gate valves, etc.

We are able to provide expertise for pumping, irrigation and water supply projects.

We have extensive experience in the field of seawater desalination and can offer products in 316L stainless steel, aluminium bronze, duplex, super duplex, etc.

Tecfly Butterfly Valve

Tecwat Double Eccentric Butterfly Valve

Resilient Seat Gate Valve

HVAC | AIR CONDITIONING

The professionals of the sector, such as design offices, installers and operators find with our products suitable solutions that meet their expectations.

Our NF and ACS certified brass valves meet the specified technical requirements.

BSP Female Balancing Valve

Flanged Balancing Valve

Genius Butterfly Valve

We have a strong presence in the pulp and paper industry.

Some of our key products, such as knife gate valves and double knife gate valves for pulper outlets, are regularly used by the industry.

Our range of ball valves as well as our ranges of hoses and steam process products are perfect complements that provide a complete solution for our customers.

Through Type

Knife Gate Valve

Stainless Steel

Knife Gate Valve

Ductile Iron

Knife Gate Valve

For several years, Tecofi has developed a range of valves to meet the needs of waste and biogas plants.

This is the case for the bi-directional knife gate valve, specially developed for the biogas application. It has a special assembly that guarantees maximum performance thanks to its Aramid fibre reinforced packing kit.

Bidirectional Knife Gate Valve

for Biogas

Butterfly Valve for Biogas

Stainless Steel Ball Valve

Sugar Industry | Food Industry | Energy Industry | Chemical Industry

We tailor our products for your applications that require materials resistant to charged water and abrasive and corrosive liquids.

The Tecflon PTFE valve, for example, is especially designed for use in the chemical industry as it is resistant to corrosion, acids and other industrial fluids. It is also suitable for applications in the sugar and food industries.

2-Piece Flanged Ball Valve

Tecflon Butterfly Valve

PTFE sleeve and disc

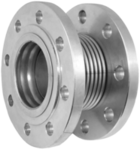

Loose-Flange Metallic Expansion Joint

We have designed products capable of responding to difficult working conditions such as lines carrying heavy and abrasive fluids (stones and pebbles).

Among these products, we have developed a knife gate valve with a rubber sleeve to protect the valve body from abrasion. The main feature of this knife gate valve is that it provides a complete and continuous passage. Thus, in the open position, it does not produce cavitation and eliminates the risk of turbulence in the fluid.

Teclarge Butterfly Valve

Pinch Knife Gate Valve

Pinch Valve

Design office

Our design office works in conjunction with our production plant. It is attentive to technological developments in order to improve our products and develop our ranges. It offers customised solutions and adapts to the constraints and specific demands of our customers.

Our teams are equipped with the best design, manufacturing, control and material resistance calculation tools and meet the highest European standards (EN1074 – EN12516.2).

Tecofi production

From the foundry to the coating, the valves are tested at each stage (body, machining, pressurisation checks, etc.).

The production units are periodically checked by an external organism and by our quality department.

Our Tecofi brand and identification plates are affixed to all our valves.

Quality Test Area

Our valves are 100% tested according to international quality control procedures. We carry out the tests in our workshops: material, dimensional, paint thickness, manoeuvring and tightness tests of our valves according to the EN 12266-1 standard.

In 2021, our two new hydraulic test benches enable us to carry out tests on our valves in semi-automatic mode up to DN1600 (PN16) / DN1000 (PN25) / DN600 (PN40).

Specific assemblies and adaptations

Our specialists carry out specific assemblies in our workshops equipped with 7 assembly lines. We offer you customised solutions, adapted to your projects, with a guaranteed short lead time! (if stock available)

We carry out all types of adaptations and accessory mountings: pneumatic actuators, solenoid valves, manual emergency controls, electric actuators, positioners, limit switches, special seals, etc.

Commissioning and maintenance assistance

Our teams are available to guide you in your choices, recommending the products best suited to your needs. Our team of specialised technicians provides on-site maintenance and operator training.

We can provide you with technical support and assistance after delivery for the commissioning of the products.